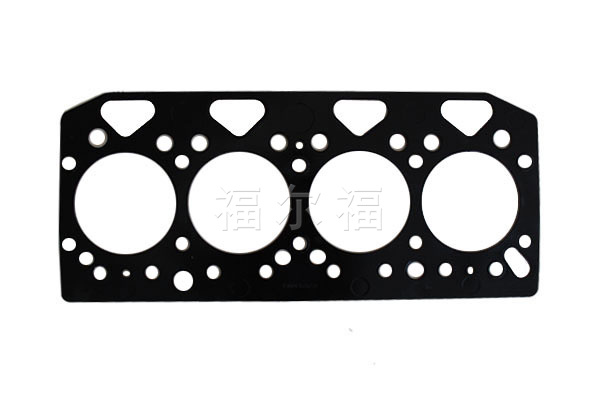

What are the common types of sealing gaskets?

2022-01-28

Sealing gasket: A sealing product made by compounding high-abrasion aramid fiber as the main material with special materials that have good lubricity. This sealing product features excellent lubricity and wear resistance. It demonstrates outstanding characteristics in liquid devices with solid-liquid phase mixtures.

Sealing gasket: A sealing product made by compounding high-abrasion aramid fiber as the main material with special materials that have good lubricity. This sealing product has good lubricity and wear resistance. It shows outstanding characteristics in liquid devices with solid-liquid phase mixtures.

Non-asbestos sheet gasket: A sealing material made by calendering aramid and other agricultural production system fibers and plant fibers with nitrile rubber and inorganic minerals at high temperature. Since it contains very little asbestos fiber, it is suitable as a substitute for asbestos gaskets. Non-asbestos gaskets have high strength, good resilience, and impermeability, making them an excellent environmentally friendly material to replace asbestos gaskets under high temperature and high pressure.

Asbestos gasket: Made by molding asbestos cloth with other auxiliary materials, used for corrosive high-pressure and high-temperature sealing. Used in reactors, reaction tanks, manholes, handholes, and other parts. Operating temperature: -100℃ to 1000℃; Operating pressure: PN<6.0Mp;

Rubber gasket: A copolymer elastomer made of vinylidene fluoride and fluorine-free, propylene fluoride, and propylene materials, widely used in defense and civilian industries. Its features include high temperature resistance, ozone resistance, natural aging resistance, vacuum resistance, fuel oil resistance, lubricating oil resistance, chemical resistance, and good electrical insulation.

PTFE-lined rubber gasket: A PTFE-lined rubber gasket is a composite gasket with polytetrafluoroethylene wrapped around rubber. It has corrosion resistance and sealing resilience, suitable for corrosion-resistant sealing of low-pressure chemical equipment such as enamel and glass pipelines.

Contact: Manager Sun

No. 8 Xiamen Street, Automotive Industrial Park, Yantai Economic and Technological Development Zone

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Online Message

* Note: Please be sure to fill in the information accurately and keep communication open, we will contact you as soon as possible

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.